SAFEMASTER W – Radio Controlled Safety System

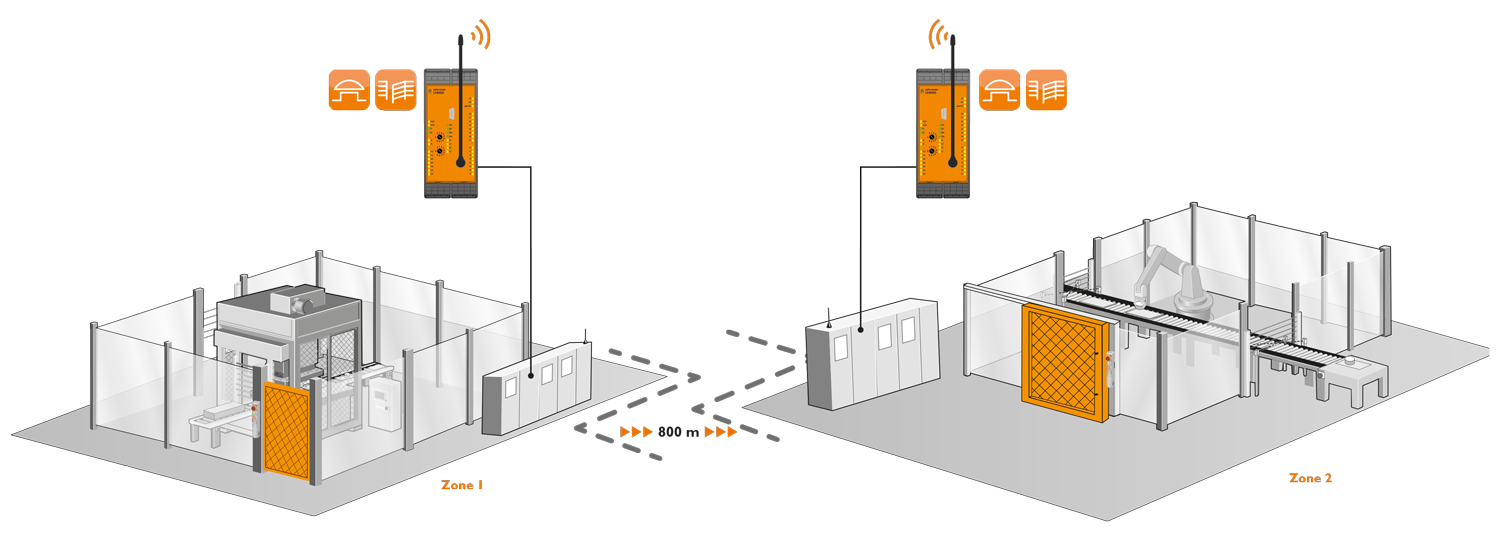

Wireless Functional Safety in pair mode

The safety approved, bidirectional radio controlled safety system UH 6900 from the SAFEMASTER W series , is for the transmission of safety inputs such as E-stop and conventional control functions and offers great flexibility for the protection of hazardous areas. By implementing the latest radio controlled technologies, a high level of safety and a long transmission range is achieved. Two safety zones can easily be connected wirelessly over a considerable distance. The main application areas include applications covering large areas and mobile applications such as fully automated conveyor systems and driverless transport systems. Simple and inexpensive retrofitting of existing safety systems can also be achieved wirelessly with this system.

Your advantages at a glance

Bidirectional

Wireless, safe signal transmission ensures high availability, even in rugged, difficult to access, and wide ranging systems

Safe signal transmission

Safe radio transmission of emergency stop functions offers additional flexibility in protecting hazardous areas

Highest safety standards

Suitable for use in safety applications up to Cat. 4 / PL e or SIL 3

Range

The range in open areas is up to 800m allowing exceptional signal coverage

Signal strength

Adjustable transmission power offers variable area coverage

Spectrum analysis

The integrated Spectrum Analyzer provides a quick overview of all available channels

Operating modes and start options

Selectable operating modes and start options allow for customised adaptation

2-Channel safety inputs

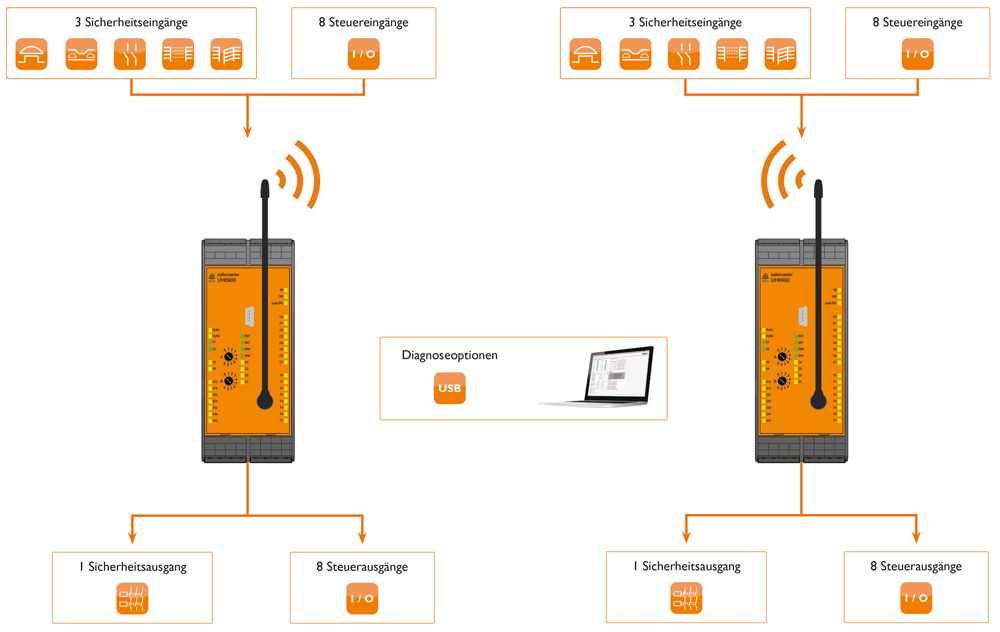

Connect up to 3 two-channel safety functions (E-stop, LC, safety gate, two-hand operation, etc.)

Control functions

Up to 8 function inputs and outputs

Forcibly guided output contacts

One safety output with 3 redundant contact paths

Diagnostic options via USB

Additional status displays and logging using the free SAFEMASTER W Manager software extends functionality

Certified safety

The SAFEMASTER W series is approved for use in safety applications up to Cat. 4 / PL e or SIL 3. The latest radio controlled technology ensures reliable protection for people, machinery, and the environment.

Scope of functions

The TÜV certified wireless safety module UH 6900 is suitable for safety requirements up to Cat. 4 / PL e or SIL 3. The safety modules each have 3 two-channel safety inputs (such as emergency stop, light curtain, safety gate, etc.) and 1 safety output with 3 redundant contact paths. In addition, the modules each provide 8 inputs and outputs for user-specific control functions. Two additional status semi-conductor outputs, one indicator output for reception quality, and the USB interface provide for comprehensive diagnostic options.

Operating modes / Start options

Safe operating modes, selectable system start – simple and functional. The following operating modes can be selected using the rotary switches:

- Full safety mode

- Cross safety mode

- Safety mode with selectableoptional radio control

This allows you to quickly adapt the system to your safety application. In addition, automatic, manual, or two-hand start options are available for system start.

Operating mode 1:

Full safety mode

Safe, wireless emergency stop – safely separate system components and zones

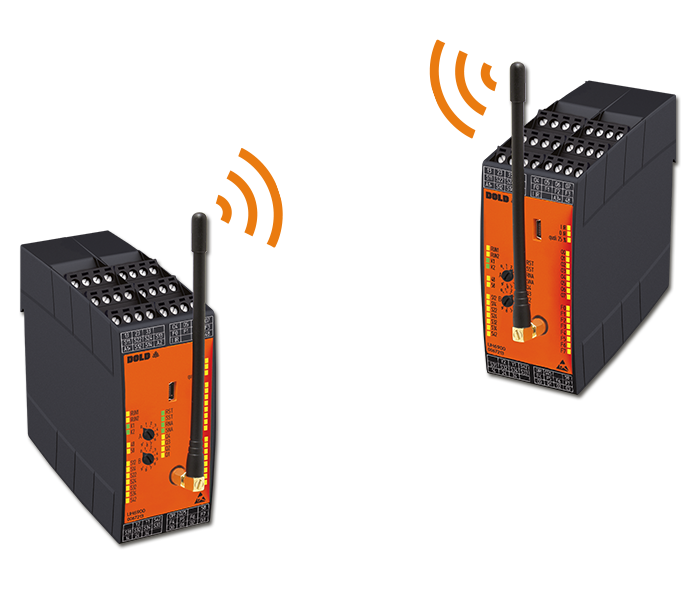

Just two UH 6900 wireless safety modules are required to fully secure two hazardous zones. Both wireless safety modules are connected by a bidirectional safe radio connection.

If a safety function is triggered (such as emergency stop, safety gate, etc.), both UH 6900 wireless safety modules shut down the entire system in both hazardous areas in a safe controlled manner.

Application example - Full safety mode:

If a safety function (emergency stop or safety gate) is activated on a system in zone 1 or zone 2, both systems are powered down in a safe and controlled manner. Only after they are shut down can persons enter the hazardous area (for instance access through releasing a safety gate lock (SAFEMASTER STS)).

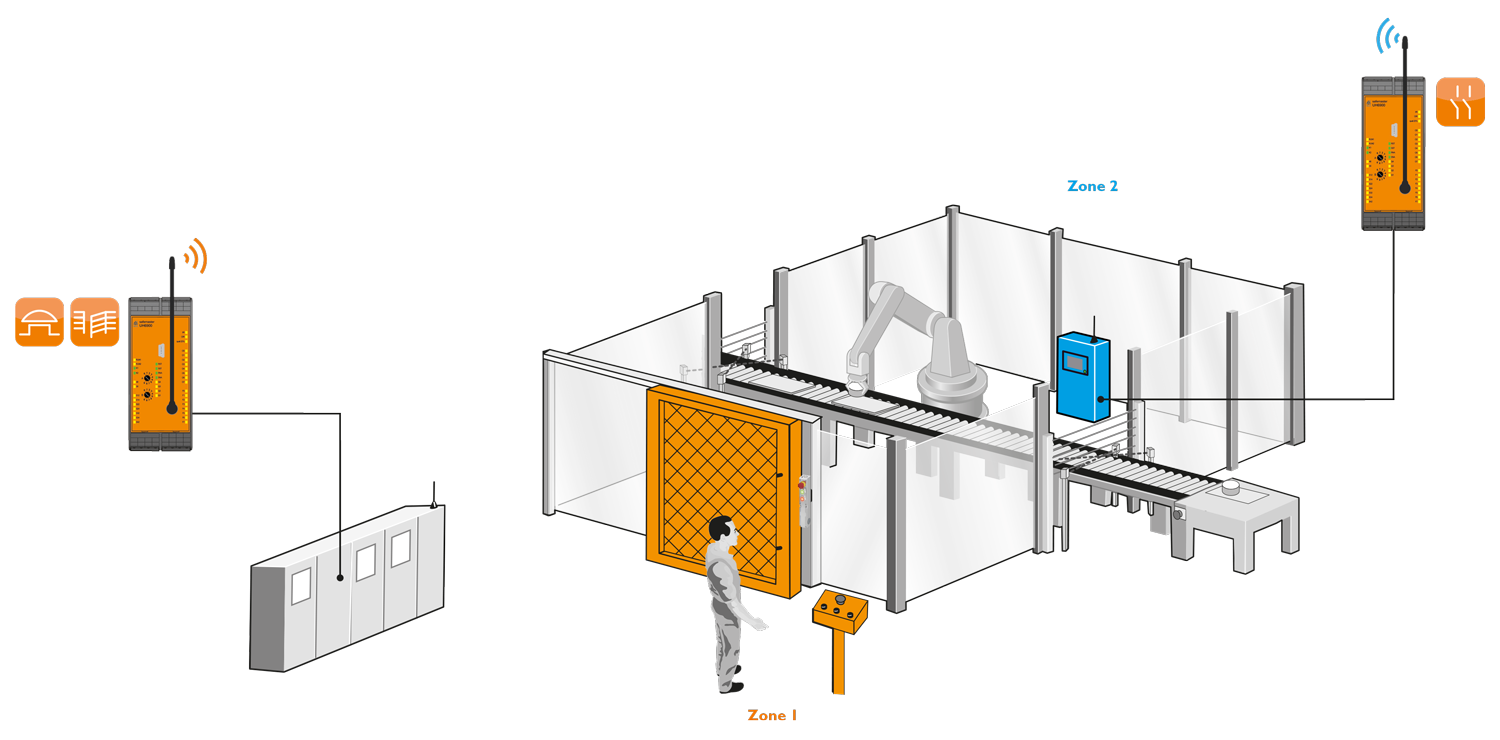

Operating mode 2:

Cross safety mode

Safe, wireless protection for hazardous areas, monitoring to multiple conditions

Even complicated tasks can be handled easily with just two wireless safety modules. A safe function (access approval, start a subsequent process, etc.) is only wirelessly released if a condition, for instance in zone 1, is fulfilled. Only then is a safety function (such as access authorisation) triggered wirelessly from the other safety zone.

An example: A conveyor belt in a hazardous area first has to be run in no-load operation and the belt stopped before safety gates can be released to allow access. In this operating mode, the system ensures that persons can only enter a hazardous area if the equipment or system is safe.

Application example - Cross safety mode

A person wants to enter a secure system area (zone 2). The person activates the emergency stop in zone 1. The emergency stop signal from zone 1 is transmitted wirelessly to zone 2. The machine in zone 2 powers down in a controlled manner. As soon as it reaches a safe status, it returns a release signal for zone 2 (for instance, approve safety gate locking). Only then can the person safely enter zone 2.

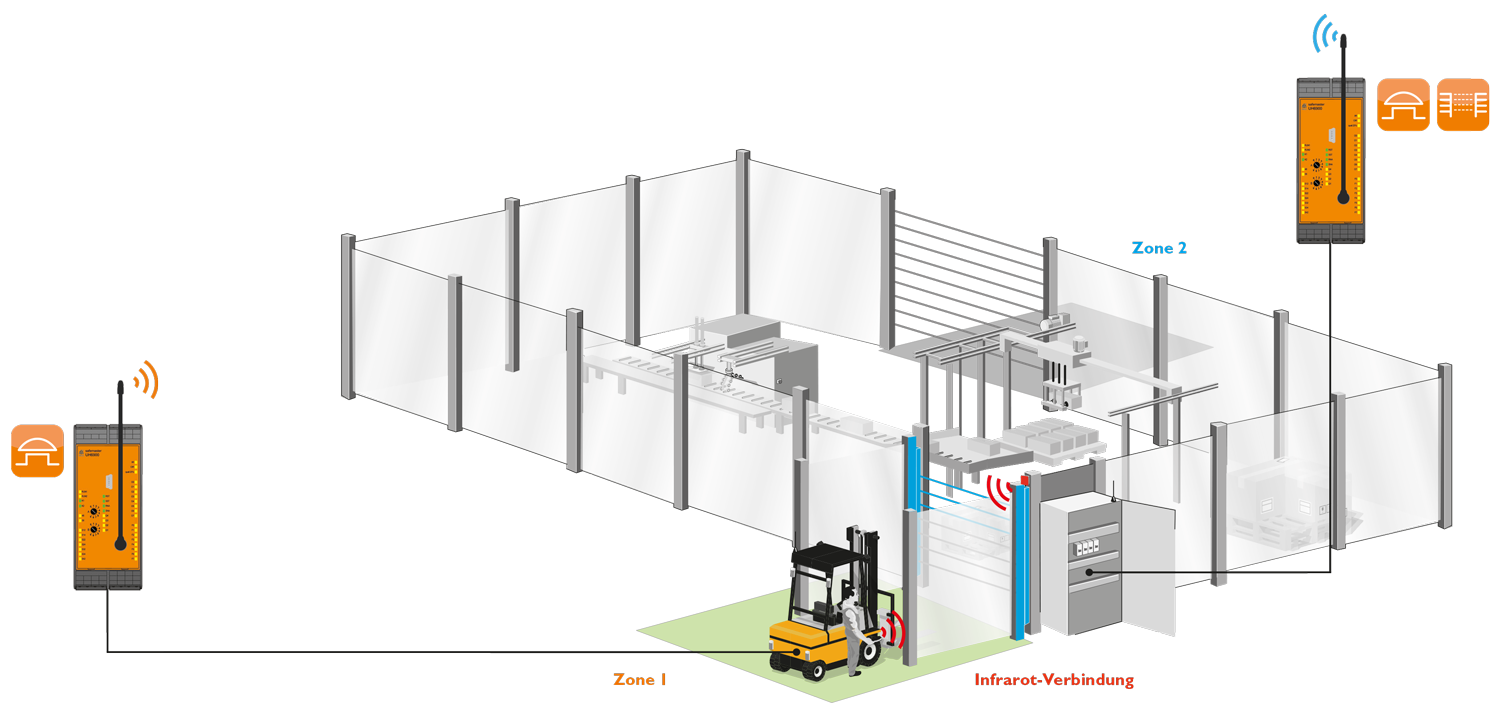

Operating mode 3:

Safety mode with wireless connection option

Link safety and control functions

A UH 6900 wireless safety module monitors a production system in a hazardous area. The device first works locally without a wireless connection with its safety inputs and output. However, there is the option to connect a second UH 6900 wireless safety module (e. g. in a forklift) to the safety functions (such as emergency stop) in the production system and safely drive through the hazardous area (additional authentication can be provided by an optional infrared connection).

When the wireless connection between the two modules is created, the safety functions of both devices will be active. In a hazardous situation, both the forklift and or the machine can trigger an emergency stop.

In addition, certain control functions of the system (such as the crane) can be used – entirely safely and without additional wiring work.

Application example - Safety mode with wireless connection option

A wireless safety module secures a production system in zone 2. It first works fully autonomously without a wireless connection. A second wireless safety module is located in the forklift. To pick up produced parts on pallets, the forklift (zone 1) has to drive into the system. In order to gain access to the system (zone 2), the forklift must connect wirelessly and position itself in the specified start zone (green) and authenticate itself via infrared connection. Access to the hazardous area is approved and the forklift can drive into zone 2. The safety functions (such as emergency stop) of both modules are now active, defined control functions can be activated by the mobile vehicle. In a hazardous situation, both the forklift and the machine operator can trigger an emergency stop. Your advantage: Access to approved control functions for the loading crane and mobility and safety in the system‘s hazardous area.

Quick start in just 3 steps

1. Quickly and easily set the operating mode using the rotary switch

2. Select frequency channel using SAFEMASTER W Manager

3. Set transmission power using SAFEMASTER W Manager

Best possible safety for all industries

-

Machine building industry

-

Intralogistics

-

Paper and printing industry

-

Food industry

-

Automotive industry

-

Recycling industry

-

Packaging machines

-

Mining and steel industry

-

Gantry cranes

-

Mountain railways and ski lifts

-

Transportation and conveying technology

-

Wind energy systems

-

Ship building and harbour systems

-

Construction materials industry

… and anywhere else where safety is the highest priority. Also in your industry!

Innovative safety solutions

As a solution provider in the field of safe automation and electrical safety, DOLD offers a comprehensive portfolio from a single source. Our SAFEMASTER solutions have been used successfully worldwide for many decades.